發表時間:2021-04-06 訪問量:

前言(yan)

液(ye)晶顯(xian)示(shi)面板上的偏(pian)(pian)(pian)光(guang)(guang)片是起偏(pian)(pian)(pian)光(guang)(guang)作用的部(bu)件,是液(ye)晶面板主要(yao)零部(bu)件之一。液(ye)晶偏(pian)(pian)(pian)光(guang)(guang)片由(you)兩層(ceng)三醋酸(suan)纖維(wei)素膜(mo)(mo)(TAC)和(he)夾在中(zhong)間(jian)的聚乙烯(xi)醇膜(mo)(mo)(PVA)組成(cheng)(cheng),其中(zhong)一側的TAC膜(mo)(mo)上附(fu)有壓(ya)(ya)(ya)敏(min)膠(jiao),用于(yu)偏(pian)(pian)(pian)光(guang)(guang)片與(yu)玻(bo)(bo)璃(li)面板的貼合。由(you)于(yu)構(gou)成(cheng)(cheng)偏(pian)(pian)(pian)光(guang)(guang)膜(mo)(mo)的基本材料(liao)PVA膜(mo)(mo)和(he)碘及(ji)碘化(hua)物都極(ji)易吸水或水解,在受熱(re)(re)、吸潮的情況下易發生變形收縮或松弛,在TAC膜(mo)(mo)、壓(ya)(ya)(ya)敏(min)膠(jiao)和(he)玻(bo)(bo)璃(li)面板之間(jian)產生應力,使得偏(pian)(pian)(pian)光(guang)(guang)片出現(xian)翹曲、氣泡,分(fen)層(ceng)、剝離等現(xian)象,所(suo)以偏(pian)(pian)(pian)光(guang)(guang)片用壓(ya)(ya)(ya)敏(min)膠(jiao)除(chu)了(le)要(yao)求具(ju)有適宜的初黏、持(chi)黏性(xing)(xing)(xing)、良好(hao)的光(guang)(guang)學(xue)(xue)(xue)性(xing)(xing)(xing)能(neng)(neng)外還(huan)要(yao)求具(ju)有較好(hao)的耐濕熱(re)(re)老化(hua)性(xing)(xing)(xing)能(neng)(neng)和(he)再剝離性(xing)(xing)(xing)能(neng)(neng)!。丙烯(xi)酸(suan)酯(zhi)類壓(ya)(ya)(ya)敏(min)膠(jiao)由(you)于(yu)兼具(ju)良好(hao)的力學(xue)(xue)(xue)性(xing)(xing)(xing)能(neng)(neng)、耐候性(xing)(xing)(xing)和(he)光(guang)(guang)學(xue)(xue)(xue)性(xing)(xing)(xing)能(neng)(neng),通過適當交聯(lian)和(he)添加改性(xing)(xing)(xing)成(cheng)(cheng)分(fen),還(huan)可提(ti)高其老化(hua)耐久性(xing)(xing)(xing),所(suo)以偏(pian)(pian)(pian)光(guang)(guang)片用壓(ya)(ya)(ya)敏(min)膠(jiao),多選(xuan)用溶(rong)劑型丙烯(xi)酸(suan)酯(zhi)壓(ya)(ya)(ya)敏(min)膠(jiao)

目(mu)前,國(guo)外偏光片用壓敏膠(jiao)的研制和(he)生(sheng)產主要集中(zhong)在電子(zi)(zi)工(gong)業發達國(guo)家如(ru)日本、韓國(guo)等,其合成和(he)改性(xing)的技術路線也不盡相(xiang)同,有(you)高相(xiang)對分子(zi)(zi)質(zhi)量(liang)(liang)丙(bing)(bing)烯(xi)酸酯(zhi)共(gong)(gong)聚物與低相(xiang)對分子(zi)(zi)質(zhi)量(liang)(liang)共(gong)(gong)混(hun)、異(yi)氰(qing)酸酯(zhi)基交聯、環氧交聯改性(xing)、加(jia)入納米粒子(zi)(zi)等多種不同方(fang)法。國(guo)內相(xiang)關研究,主要有(you)紫外光固化型(xing)聚丙(bing)(bing)烯(xi)酸酯(zhi)、不同相(xiang)對分子(zi)(zi)質(zhi)量(liang)(liang)丙(bing)(bing)烯(xi)酸酯(zhi)共(gong)(gong)聚物共(gong)(gong)混(hun)等方(fang)法,研究重點(dian)集中(zhong)在單體的配合和(he)粘接(jie)性(xing)能。

本文(wen)從配方設(she)計人手,采用丙(bing)烯(xi)(xi)酸(suan)(suan)丁酯(zhi)(zhi)、丙(bing)烯(xi)(xi)酸(suan)(suan)異辛酯(zhi)(zhi)、甲(jia)(jia)基(ji)丙(bing)烯(xi)(xi)酸(suan)(suan)甲(jia)(jia)酯(zhi)(zhi)、甲(jia)(jia)基(ji)丙(bing)烯(xi)(xi)酸(suan)(suan)羥丙(bing)酯(zhi)(zhi)、丙(bing)烯(xi)(xi)酸(suan)(suan)等單體(ti)通過溶液聚合的(de)(de)方法(fa),制(zhi)得(de)了不同(tong)的(de)(de)丙(bing)烯(xi)(xi)酸(suan)(suan)酯(zhi)(zhi)壓(ya)敏膠(PSA).討論了引發劑、官能(neng)(neng)單體(ti)AA、交聯方法(fa)等因素PSA的(de)(de)粘接(jie)性(xing)(xing)能(neng)(neng)、光(guang)學性(xing)(xing)能(neng)(neng)的(de)(de)影(ying)響,著重討論了交聯方法(fa)對熱老化和濕熱老化性(xing)(xing)能(neng)(neng)的(de)(de)影(ying)響。制(zhi)備(bei)的(de)(de)壓(ya)敏膠具有均衡的(de)(de)內聚強度(du)和粘接(jie)性(xing)(xing)能(neng)(neng),并具有良好的(de)(de)濕熱老化性(xing)(xing)能(neng)(neng)。

1實驗部分

1.1主要原料及(ji)儀器

丙烯(xi)酸(suan)(suan)丁酯(zhi)(zhi)(BA),分(fen)析(xi)(xi)純(chun)(chun)(chun);丙烯(xi)酸(suan)(suan)異(yi)辛酯(zhi)(zhi)(2-EHA),化(hua)(hua)學(xue)純(chun)(chun)(chun);丙烯(xi)酸(suan)(suan)(AA),分(fen)析(xi)(xi)純(chun)(chun)(chun);甲基(ji)(ji)丙烯(xi)酸(suan)(suan)甲酯(zhi)(zhi)(MMA),分(fen)析(xi)(xi)純(chun)(chun)(chun);甲基(ji)(ji)丙烯(xi)酸(suan)(suan)羥(qian)丙酯(zhi)(zhi)(HPMA),化(hua)(hua)學(xue)純(chun)(chun)(chun);異(yi)氟爾酮二異(yi)氰酸(suan)(suan)酯(zhi)(zhi)(IPDI),分(fen)析(xi)(xi)純(chun)(chun)(chun);甲苯二異(yi)氰酸(suan)(suan)酯(zhi)(zhi)(TDI),分(fen)析(xi)(xi)純(chun)(chun)(chun);KH-570;過氧(yang)化(hua)(hua)苯甲酰(BPO),分(fen)析(xi)(xi)純(chun)(chun)(chun);偶(ou)氮二異(yi)丁腈(AIBN),化(hua)(hua)學(xue)純(chun)(chun)(chun):乙酸(suan)(suan)乙酯(zhi)(zhi),分(fen)析(xi)(xi)純(chun)(chun)(chun)。NDJ-5S型旋轉式黏(nian)度(du)計(ji);傅里(li)葉變(bian)換紅(hong)外(wai)光(guang)譜(pu)儀;高低(di)溫濕(shi)熱(re)老化(hua)(hua)箱(xiang);精密烤箱(xiang);凝膠色譜(pu)儀1515。

旋轉式粘度計

精密烘箱

可程式恒溫恒濕試驗箱

1.2壓敏膠(jiao)液(ye)的制備

在通氮狀態下(xia),將全部單體、1/3乙酸乙酯溶劑(ji)(ji)、1/3引(yin)發劑(ji)(ji)、硅(gui)烷偶聯劑(ji)(ji)按照配(pei)比投入(ru)到三(san)口燒(shao)瓶中,攪(jiao)拌(ban)、升溫(wen)(wen)(wen)(wen),待達到反(fan)(fan)應(ying)(ying)溫(wen)(wen)(wen)(wen)度后(hou),保溫(wen)(wen)(wen)(wen)反(fan)(fan)應(ying)(ying)2h,再(zai)加(jia)入(ru)1/3引(yin)發劑(ji)(ji)及(ji)1/3溶劑(ji)(ji),反(fan)(fan)應(ying)(ying)2h,加(jia)入(ru)剩余(yu)引(yin)發劑(ji)(ji)及(ji)溶劑(ji)(ji),保溫(wen)(wen)(wen)(wen)反(fan)(fan)應(ying)(ying)2h,再(zai)升高(gao)到合適溫(wen)(wen)(wen)(wen)度,保溫(wen)(wen)(wen)(wen)反(fan)(fan)應(ying)(ying)2h.然后(hou)冷卻至室(shi)溫(wen)(wen)(wen)(wen),出料。

1.3壓敏膠帶的制備

將配制好的壓敏(min)膠(jiao)液(ye)(ye)用專用刮刀均勻涂(tu)布在PET膜(mo)(或液(ye)(ye)晶偏振片)上,放置于120℃精(jing)密烤(kao)箱中(zhong)烘3min,烘干后的膠(jiao)層厚度(du)為20~25um.涂(tu)布干燥后的膠(jiao)帶貼覆于離型紙上備用。

小型真空吸附涂布機(ji) 恒溫(wen)型膠(jiao)帶保持力試驗機(ji)10組

1.4性能測試高溫持粘力試驗機

(1)固含量

取(qu)1.0~1.5g壓敏膠液(ye)(ye),置于(yu)已(yi)知質量的(de)干(gan)(gan)(gan)(gan)燥(zao)(zao)(zao)潔凈PET膜上,放(fang)(fang)置于(yu)120℃恒溫(wen)(wen)干(gan)(gan)(gan)(gan)燥(zao)(zao)(zao)箱(xiang)中,每隔30min取(qu)出放(fang)(fang)入干(gan)(gan)(gan)(gan)燥(zao)(zao)(zao)器中,冷卻(que)至(zhi)室(shi)溫(wen)(wen)稱(cheng)量,然后再將其(qi)放(fang)(fang)入120℃的(de)干(gan)(gan)(gan)(gan)燥(zao)(zao)(zao)箱(xiang)中加熱烘干(gan)(gan)(gan)(gan)30min,取(qu)出放(fang)(fang)人(ren)干(gan)(gan)(gan)(gan)燥(zao)(zao)(zao)器中,冷卻(que)至(zhi)室(shi)溫(wen)(wen)稱(cheng)量。反復操(cao)作直至(zhi)兩次稱(cheng)量質量之差小于(yu)0.01g為止(zhi)。按下(xia)式計算壓敏膠液(ye)(ye)的(de)固(gu)含(han)量:

W=m2-mo/m1-mo×100%

式中(zhong):W-固含(han)量,%

mo-原PET膜的質(zhi)量,g

m1-烘干前膠液與(yu)PET膜的總(zong)質量,g

m2-烘(hong)干后膠液(ye)與(yu)PET膜的總質量,g

(2)轉化(hua)率

轉化率為發生反(fan)應的(de)單體總(zong)質(zhi)(zhi)量占起始反(fan)應單體的(de)總(zong)質(zhi)(zhi)量的(de)比(bi)例。由下式計算(suan):

a=W1/W2*100%

式(shi)中:a-轉化率,%

W1一反應結束后膠液(ye)的(de)固含(han)量,%

W2一(yi)反應(ying)起(qi)始時(shi)體(ti)系的(de)固含量,%

(3)黏度

采用(yong)旋轉黏度(du)計測試。

(4)初黏力:按照GB/T4852-2002進行測(ce)試,其中測(ce)量角為30°

持黏力:按照GB/T4581-1998進行測試,其中負(fu)重為(wei)1kg.

180°剝離強(qiang)度:按照CB/T2792-2014進(jin)行測(ce)試,其中夾頭速(su)度300mm/min.

(5)相(xiang)對分子質量:采用(yong)GPC1515儀器進(jin)行測定。

(6)耐老化(hua)

將(jiang)(jiang)涂布干(gan)PET或偏光(guang)片基材上(shang)(shang)的壓(ya)敏膠(jiao)裁剪成尺(chi)寸為25mm(寬)x180mm(長)的膠(jiao)條,烘干(gan)。用2kg膠(jiao)輥(gun)將(jiang)(jiang)樣品輥(gun)壓(ya)貼附(fu)到玻(bo)璃板(ban)上(shang)(shang),制成壓(ya)敏膠(jiao)粘帶制件(jian)。

耐熱性:將壓敏(min)膠粘(zhan)帶制件放置于80℃恒(heng)溫干(gan)燥箱(xiang)中500h.

耐濕(shi)熱老化:將壓敏膠(jiao)粘帶制(zhi)件放置于80℃濕(shi)度90%的恒溫恒濕(shi)箱中(zhong)500h.

(7)重貼性

按(6)中(zhong)方(fang)法制備敏膠粘帶制件(jian),然后從(cong)一端將膠片撕(si)起90mm,再(zai)用2kg膠輥將樣(yang)品貼在(zai)玻璃上,反(fan)復剝離60次,觀測膠層是(shi)否破壞(huai)。

二、結果與討論

2.1壓敏膠的基本性能及影(ying)響因素

2.1.1引(yin)發劑對壓敏膠性能的(de)影(ying)響

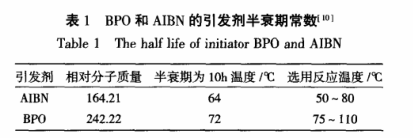

丙烯酸(suan)酯類壓敏膠通常(chang)選用BPO及AIBN為引(yin)發(fa)劑(ji),兩種引(yin)發(fa)劑(ji)的相關參數如表(biao)1.

從表中可知(zhi),AIBN活(huo)性(xing)(xing)要高于BPO,適(shi)宜反應溫度為(wei)67℃左右,未達到乙(yi)酸(suan)乙(yi)酯的(de)沸(fei)點,無法(fa)形成蒸汽氛圍,通過實驗(yan)發(fa)(fa)現(xian),選(xuan)用AIBN為(wei)引發(fa)(fa)劑(ji)時(shi),膠液呈現(xian)淡黃(huang)色(se)(se),因(yin)為(wei)AIBN分解之后會變成2個丁腈自由(you)基,腈很(hen)容易(yi)變黃(huang),而選(xuan)用BPO為(wei)引發(fa)(fa)劑(ji)時(shi),膠液外(wai)觀(guan)為(wei)無色(se)(se)透(tou)明(ming)狀態。偏光(guang)片(pian)用壓(ya)敏膠要求(qiu)具有良好的(de)光(guang)學特性(xing)(xing),無色(se)(se)透(tou)明(ming)且(qie)耐久(jiu)無黃(huang)變。因(yin)此選(xuan)用BPO為(wei)聚(ju)合體系(xi)的(de)引發(fa)(fa)劑(ji)。引發(fa)(fa)劑(ji)用量對壓(ya)敏膠性(xing)(xing)能的(de)影(ying)響如表2.

在實驗條件下,引(yin)發(fa)劑用(yong)量(liang)為0.5份(fen)時(shi),轉化(hua)率(lv)較(jiao)(jiao)低(di),而(er)黏(nian)(nian)度(du)(du)(du)(du)(du)、持黏(nian)(nian)力及(ji)剝(bo)離(li)強度(du)(du)(du)(du)(du)都(dou)(dou)較(jiao)(jiao)高,引(yin)發(fa)劑用(yong)量(liang)為0.8時(shi),轉化(hua)率(lv)較(jiao)(jiao)高,而(er)黏(nian)(nian)度(du)(du)(du)(du)(du)、持黏(nian)(nian)力及(ji)剝(bo)離(li)強度(du)(du)(du)(du)(du)都(dou)(dou)較(jiao)(jiao)低(di)。引(yin)發(fa)劑的(de)(de)濃度(du)(du)(du)(du)(du)與動(dong)力學鏈長成(cheng)反比,所以濃度(du)(du)(du)(du)(du)越高,相對(dui)分子質量(liang)越低(di),導致壓(ya)敏(min)膠的(de)(de)內聚力降(jiang)低(di)。因而(er),隨著引(yin)發(fa)劑用(yong)量(liang)的(de)(de)增加(jia),壓(ya)敏(min)膠的(de)(de)持黏(nian)(nian)力、剝(bo)離(li)強度(du)(du)(du)(du)(du)及(ji)黏(nian)(nian)度(du)(du)(du)(du)(du)均降(jiang)低(di),而(er)低(di)相對(dui)分子質量(liang)的(de)(de)壓(ya)敏(min)膠液(ye)有助于浸潤基材,導致初(chu)黏(nian)(nian)呈上升趨勢(shi),引(yin)起再剝(bo)離(li)性(xing)較(jiao)(jiao)差(cha)。綜合(he)考(kao)慮轉化(hua)率(lv)與性(xing)能之間的(de)(de)關系,確定引(yin)發(fa)劑的(de)(de)用(yong)量(liang)為0.6份(fen)。

2.1.2單體組成(cheng)對壓敏膠(jiao)影響

(1)壓敏(min)膠基(ji)本組成

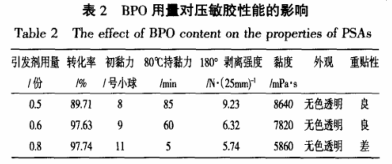

根據施(shi)工方法和(he)(he)使用(yong)環(huan)境,偏(pian)光片用(yong)丙烯酸酯壓(ya)(ya)敏(min)膠(jiao)應具有(you)適宜的(de)初黏性(xing)和(he)(he)剝離強度(5N/25mm~10N/25mm)、較高的(de)高溫持黏性(xing),并能耐受多次重復剝離和(he)(he)耐黃變。綜合以(yi)上要求,實驗(yan)選(xuan)用(yong)軟單(dan)(dan)(dan)體(ti)以(yi)BA為(wei)主,配合少量(liang)(liang)2-EHA,硬單(dan)(dan)(dan)體(ti)選(xuan)用(yong)MMA,官能單(dan)(dan)(dan)體(ti)選(xuan)用(yong)AA和(he)(he)HPMA,通過調節各(ge)單(dan)(dan)(dan)體(ti)間(jian)的(de)配比,使得(de)壓(ya)(ya)敏(min)膠(jiao)具有(you)較為(wei)均衡的(de)內聚力(li)和(he)(he)粘接力(li),滿(man)足基本的(de)粘接性(xing)能要求。(2)AA用(yong)量(liang)(liang)對(dui)(dui)壓(ya)(ya)敏(min)膠(jiao)性(xing)能的(de)影響在實驗(yan)過程中,AA用(yong)量(liang)(liang)對(dui)(dui)壓(ya)(ya)敏(min)膠(jiao)的(de)整體(ti)性(xing)能

影響較(jiao)大,AA用量對壓敏(min)膠性能(neng)的影響見表3.

由表(biao)中數據可知,隨著(zhu)AA用量(liang)的增加,壓(ya)敏膠(jiao)的初黏力下(xia)降,持黏力和剝離強(qiang)度均增加。這與AA在(zai)整個聚合物單(dan)體(ti)(ti)體(ti)(ti)系(xi)中,既是官能單(dan)體(ti)(ti),又是硬單(dan)體(ti)(ti)有關。然而隨著(zhu)AA含(han)量(liang)的增加,部分AA分子中的羧基形成化學鍵(jian)111導致體(ti)(ti)系(xi)的黏度增加較大,在(zai)加入(ru)量(liang)達到(dao)1份(fen)時(shi),膠(jiao)液已為微凝膠(jiao)狀態,不利(li)于涂布,因此選(xuan)定AA的加入(ru)量(liang)為0.5份(fen)。

2.2壓敏膠的交(jiao)聯(lian)控(kong)制及耐老(lao)化(hua)性能

2.2.1

交聯控制

丙(bing)烯酸酯自由基(ji)共聚后(hou)導人的(de)(de)官能(neng)團可(ke)(ke)通過加入雙官能(neng)以上(shang)的(de)(de)活性單體或聚合(he)物(wu)實現交(jiao)聯。適(shi)度的(de)(de)交(jiao)聯可(ke)(ke)顯著提高共聚物(wu)的(de)(de)相(xiang)對分子質量和壓敏膠的(de)(de)持黏力(li),此外,交(jiao)聯還能(neng)增強壓敏膠的(de)(de)耐溶劑(ji)能(neng)力(li)、抗老化性能(neng)以及對基(ji)材的(de)(de)附(fu)著力(li).

(1)交聯方法

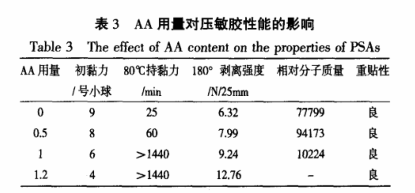

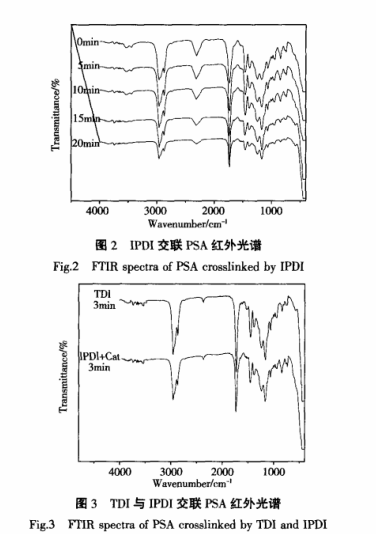

實(shi)驗中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)丙(bing)烯(xi)(xi)(xi)酸(suan)(suan)酯(zhi)壓(ya)(ya)敏膠(jiao)共聚(ju)物(wu)導人羥基(ji)(ji)(ji)和羧基(ji)(ji)(ji),選用異(yi)氰酸(suan)(suan)酯(zhi)為交聯(lian)(lian)劑(ji),以(yi)調節粘接(jie)性(xing)(xing)(xing)能和老化性(xing)(xing)(xing)能。TDI和IPDI兩種(zhong)異(yi)氰酸(suan)(suan)酯(zhi)交聯(lian)(lian)劑(ji)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)-NCO基(ji)(ji)(ji)具有不同(tong)的(de)(de)(de)(de)(de)反(fan)(fan)(fan)應(ying)(ying)(ying)活(huo)性(xing)(xing)(xing),在相同(tong)的(de)(de)(de)(de)(de)反(fan)(fan)(fan)應(ying)(ying)(ying)條件下(xia),其(qi)活(huo)性(xing)(xing)(xing)視(shi)分子中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)其(qi)它基(ji)(ji)(ji)團的(de)(de)(de)(de)(de)性(xing)(xing)(xing)質呈(cheng)下(xia)列趨勢:對硝基(ji)(ji)(ji)苯基(ji)(ji)(ji)>苯基(ji)(ji)(ji)>對甲(jia)基(ji)(ji)(ji)苯基(ji)(ji)(ji)>苯甲(jia)基(ji)(ji)(ji)>環己(ji)基(ji)(ji)(ji)>烷基(ji)(ji)(ji),所(suo)以(yi)TDI中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)-NCO的(de)(de)(de)(de)(de)活(huo)性(xing)(xing)(xing)較高。圖(tu)2為采(cai)用IPDI交聯(lian)(lian)的(de)(de)(de)(de)(de)丙(bing)烯(xi)(xi)(xi)酸(suan)(suan)酯(zhi)壓(ya)(ya)敏膠(jiao)薄膜在120℃恒溫干(gan)燥(zao)箱(xiang)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)放(fang)置不同(tong)時間(jian)的(de)(de)(de)(de)(de)紅外譜圖(tu),其(qi)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)交聯(lian)(lian)劑(ji)加人量(liang)按官能團物(wu)質的(de)(de)(de)(de)(de)量(liang)比計過量(liang)5%.圖(tu)中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)IPDI在120℃反(fan)(fan)(fan)應(ying)(ying)(ying)5min的(de)(de)(de)(de)(de)條件下(xia),異(yi)氰酸(suan)(suan)酯(zhi)基(ji)(ji)(ji)反(fan)(fan)(fan)應(ying)(ying)(ying)較少,說明(ming)反(fan)(fan)(fan)應(ying)(ying)(ying)程度低,到20min時,3400cm處的(de)(de)(de)(de)(de)羥基(ji)(ji)(ji)峰基(ji)(ji)(ji)本消失,說明(ming)IPDI中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)NCO的(de)(de)(de)(de)(de)交聯(lian)(lian)反(fan)(fan)(fan)應(ying)(ying)(ying)才基(ji)(ji)(ji)本完(wan)(wan)全。要滿足實(shi)際(ji)涂(tu)布(bu)工藝和熱(re)風烘(hong)(hong)道烘(hong)(hong)干(gan)的(de)(de)(de)(de)(de)要求,需縮短交聯(lian)(lian)反(fan)(fan)(fan)應(ying)(ying)(ying)時間(jian),加快固化速度,所(suo)以(yi)采(cai)用IPDI作為交聯(lian)(lian)劑(ji)時,加入催化劑(ji)M,以(yi)促進(jin)其(qi)反(fan)(fan)(fan)應(ying)(ying)(ying)。圖(tu)3為采(cai)用TDI和催化條件下(xia)IPDI交聯(lian)(lian)的(de)(de)(de)(de)(de)丙(bing)烯(xi)(xi)(xi)酸(suan)(suan)酯(zhi)壓(ya)(ya)敏膠(jiao)在120℃放(fang)置3min后的(de)(de)(de)(de)(de)紅外譜圖(tu)。從(cong)圖(tu)3中(zhong)(zhong)(zhong)(zhong)(zhong)(zhong)可以(yi)看(kan)出(chu),采(cai)用TDI和IPDI催化交聯(lian)(lian)時,3400cm處的(de)(de)(de)(de)(de)羥基(ji)(ji)(ji)均已消失,交聯(lian)(lian)反(fan)(fan)(fan)應(ying)(ying)(ying)進(jin)行基(ji)(ji)(ji)本完(wan)(wan)全。

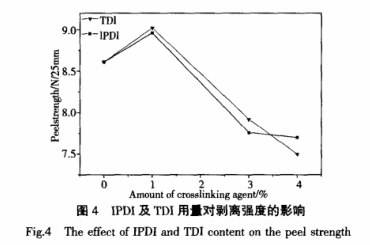

圖4考察(cha)了兩種交(jiao)(jiao)聯(lian)(lian)劑(ji)加人(ren)量對壓(ya)敏膠(jiao)剝離強(qiang)度的影響。從圖中可以(yi)看出,兩種交(jiao)(jiao)聯(lian)(lian)劑(ji)對壓(ya)敏膠(jiao)剝離強(qiang)度的影響趨勢(shi)相(xiang)同(tong),然(ran)而,經TDI交(jiao)(jiao)聯(lian)(lian)后的壓(ya)敏膠(jiao)經紫(zi)外(wai)光(guang)(guang)(10mW/C㎡)照(zhao)射24h后膠(jiao)層呈(cheng)現(xian)淡黃色。分析其(qi)原因(yin)(yin)為(wei)TDI分子鏈中含有苯環,苯環中的不飽和鍵在紫(zi)外(wai)光(guang)(guang)照(zhao)射下易(yi)發(fa)生黃變。影響了壓(ya)敏膠(jiao)的透(tou)光(guang)(guang)率,而用IPDI交(jiao)(jiao)聯(lian)(lian)的膠(jiao)層經紫(zi)外(wai)光(guang)(guang)照(zhao)射后未發(fa)生變色現(xian)象。因(yin)(yin)此,選(xuan)用IPDI為(wei)壓(ya)敏膠(jiao)的交(jiao)(jiao)聯(lian)(lian)劑(ji)。

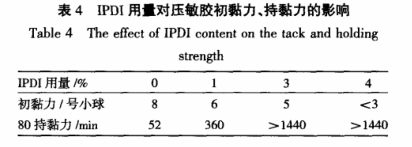

(2)IPDI用(yong)(yong)量(liang)對壓(ya)(ya)(ya)敏(min)(min)膠(jiao)粘接性能的(de)影(ying)響IPDI用(yong)(yong)量(liang)對壓(ya)(ya)(ya)敏(min)(min)膠(jiao)初(chu)黏(nian)力(li)及持黏(nian)力(li)的(de)影(ying)響見(jian)表4.未交(jiao)聯(lian)的(de)壓(ya)(ya)(ya)敏(min)(min)膠(jiao),初(chu)黏(nian)力(li)較高(gao),高(gao)溫持黏(nian)性很低(di)(di),在80℃時的(de)持黏(nian)只有(you)52min.隨(sui)著(zhu)IPDI用(yong)(yong)量(liang)的(de)增加,壓(ya)(ya)(ya)敏(min)(min)膠(jiao)的(de)初(chu)黏(nian)力(li)下降(jiang),持黏(nian)力(li)升高(gao)。當用(yong)(yong)量(liang)為固(gu)含量(liang)的(de)4%時,初(chu)黏(nian)力(li)過低(di)(di),小于3號小球,所(suo)以選(xuan)用(yong)(yong)3%的(de)IPDI用(yong)(yong)量(liang)。

2.2.2壓(ya)敏膠的耐老(lao)化(hua)性(xing)能

對壓敏膠進行熱老化及濕熱老化測試,考察(cha)老化前后的剝離強(qiang)度。

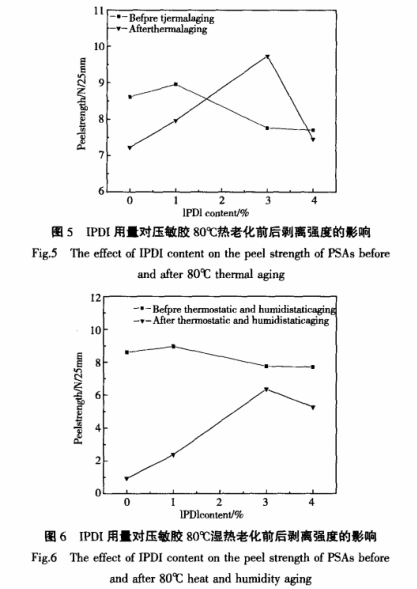

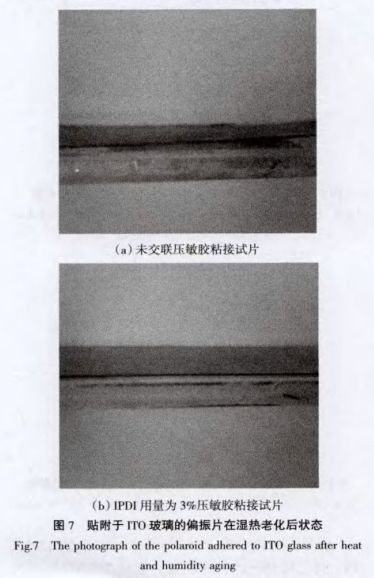

從(cong)圖5可(ke)以(yi)看出,交(jiao)聯(lian)(lian)劑(ji)用量為固含量3%時(shi)(shi),進行80℃熱(re)老(lao)化(hua)(hua)(hua)后,其(qi)剝(bo)離(li)強(qiang)度(du)從(cong)7.76N/25mm升高(gao)至9.74N/25mm,其(qi)原因可(ke)能是(shi)壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao)中未(wei)完全反(fan)應(ying)的(de)(de)(de)(de)IPDI中的(de)(de)(de)(de)異氰酸酯(zhi)基長期置(zhi)于高(gao)溫環(huan)境中繼續反(fan)應(ying),使相對分子質量進一步增加,剝(bo)離(li)強(qiang)度(du)升高(gao)。當交(jiao)聯(lian)(lian)劑(ji)用量較(jiao)大(da)時(shi)(shi),由于分子內聚力較(jiao)大(da),使壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao)體(ti)系韌性(xing)降低(di),剝(bo)離(li)強(qiang)度(du)隨之下(xia)(xia)降。圖6中,交(jiao)聯(lian)(lian)劑(ji)用量為固含量3%時(shi)(shi),濕(shi)(shi)(shi)(shi)(shi)熱(re)老(lao)化(hua)(hua)(hua)前剝(bo)離(li)強(qiang)度(du)為7.76N/25mm,經(jing)過80℃/RH90%條件(jian)下(xia)(xia)濕(shi)(shi)(shi)(shi)(shi)熱(re)老(lao)化(hua)(hua)(hua)500h后,剝(bo)離(li)強(qiang)度(du)為6.36N/25mm,強(qiang)度(du)保持(chi)率為82%,仍(reng)高(gao)于偏(pian)(pian)(pian)光(guang)(guang)片(pian)(pian)用壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao)所需剝(bo)離(li)強(qiang)度(du)的(de)(de)(de)(de)下(xia)(xia)限5N/25mm,說明壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao)形(xing)成較(jiao)穩(wen)定的(de)(de)(de)(de)交(jiao)聯(lian)(lian)網絡。為考察(cha)壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao)在(zai)偏(pian)(pian)(pian)光(guang)(guang)片(pian)(pian)上(shang)的(de)(de)(de)(de)實(shi)際(ji)耐(nai)環(huan)境性(xing)能,將壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao)涂布(bu)于偏(pian)(pian)(pian)光(guang)(guang)片(pian)(pian),恒溫干燥后,貼(tie)合到液晶玻璃板上(shang),測定其(qi)80%℃/RH95%條件(jian)下(xia)(xia)的(de)(de)(de)(de)耐(nai)濕(shi)(shi)(shi)(shi)(shi)熱(re)老(lao)化(hua)(hua)(hua)性(xing)能(圖7).圖片(pian)(pian)顯示的(de)(de)(de)(de)是(shi)未(wei)交(jiao)聯(lian)(lian)和加入3%IPDI交(jiao)聯(lian)(lian)劑(ji)催化(hua)(hua)(hua)交(jiao)聯(lian)(lian)的(de)(de)(de)(de)壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao),經(jing)過80℃/RH95%濕(shi)(shi)(shi)(shi)(shi)熱(re)條件(jian)下(xia)(xia)老(lao)化(hua)(hua)(hua)500h后的(de)(de)(de)(de)試片(pian)(pian)狀態。未(wei)加交(jiao)聯(lian)(lian)劑(ji)時(shi)(shi)偏(pian)(pian)(pian)光(guang)(guang)片(pian)(pian)已(yi)發生顯著翹曲變形(xing)(圖7(a));而加入3%IPDI交(jiao)聯(lian)(lian)的(de)(de)(de)(de)壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao),偏(pian)(pian)(pian)光(guang)(guang)片(pian)(pian)仍(reng)很(hen)好的(de)(de)(de)(de)貼(tie)附在(zai)玻璃片(pian)(pian)上(shang),無明顯翹曲(圖7(b)),說明涂布(bu)于偏(pian)(pian)(pian)光(guang)(guang)片(pian)(pian)上(shang)的(de)(de)(de)(de)壓(ya)敏(min)(min)(min)(min)膠(jiao)(jiao)具(ju)有良好的(de)(de)(de)(de)耐(nai)濕(shi)(shi)(shi)(shi)(shi)熱(re)老(lao)化(hua)(hua)(hua)性(xing)能。

3結(jie)論

(1)在固定(ding)軟硬單體比例(li)條件下,單體AA用(yong)量(liang)對(dui)壓敏(min)膠的(de)性(xing)能(neng)影響(xiang)較(jiao)大,增加AA用(yong)量(liang),體系初黏力下降(jiang),持黏力及剝離強度升高,當AA用(yong)量(liang)為(wei)0.5份時,壓敏(min)膠具有良好的(de)涂布工藝性(xing)和均(jun)衡的(de)力學性(xing)能(neng)。

(2)采用IPDI和催化劑交聯(lian),可有(you)(you)效地提高(gao)壓敏(min)膠(jiao)的(de)持黏(nian)性(xing)和耐老(lao)化性(xing)。當IPDI用量(liang)為(wei)(wei)固含量(liang)的(de)3%時,制備的(de)壓敏(min)膠(jiao)具(ju)有(you)(you)適宜的(de)粘接性(xing)能(neng)(neng),熱老(lao)化前后,PET基(ji)材(cai)壓敏(min)膠(jiao)的(de)剝離強度分(fen)別為(wei)(wei)7.76N/25mm,9.74N/25mm濕(shi)熱老(lao)化前后,PET基(ji)材(cai)壓敏(min)膠(jiao)的(de)剝離強度分(fen)別為(wei)(wei)7.76N/25mm,6.36N/25mm,具(ju)有(you)(you)較高(gao)剝離強度保持率。該壓敏(min)膠(jiao)用于偏光(guang)片和玻璃板貼附時,未出現翹曲、變形、氣泡等不良變化,顯示出優(you)良的(de)濕(shi)熱老(lao)化性(xing)能(neng)(neng)。

膠粘事業部

華南負責人:詹紅兵15118409165

華(hua)東負責人:張(zhang)振13073353892

家具·箱(xiang)包·塑料(liao)·包裝事業部

華南負(fu)責人(ren):蔡(cai)婷婷13929477992

華東負(fu)責人:陳濤13790278052

郵箱(xiang):kejian@hrbhaidu.com